Machinery and equipment for plastics processing

Injection Moulding Machine

Arburg | Allrounder 470 E 1000-290 (GE)

| Electric Injection Molding Machine – designed for injection molding of thermoplastic parts with spindle reducers and servo motors with automatic control of closing force. | |

| Distance between tie bars: | (470 x 470) mm |

| Clamping force: | 1 000 kN |

| Mould mounting platens: | (637 x 637) mm |

| Maximal calculated stroke volume: | 144 cm3 |

| Acquisition year: | 2018 |

| The contact person: | Michal Staněk, stanek@utb.cz |

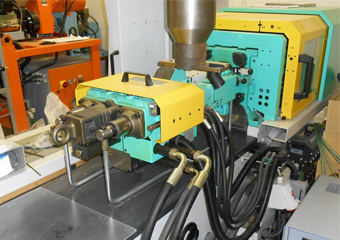

Injection Moulding Machine

Arburg | Allrounder 170 U 150-30

| Hydraulic Injection Moulding Machine – desgned for injection molding of thermoplastic parts. | |

| Distance between tie bars: | (170 x 170) mm |

| Clamping force: | 150 kN |

| Mould mounting platens: | (275 x 275) mm |

| Maximal calculated stroke volume: | 15.3 cm3 |

| Acquisition year: | 2006 |

| The contact person: | Michal Staněk, stanek@utb.cz |

Combined Drying and Conveying Machine

Arburg | Thermolift 100-2

| Combined Drying and Conveying – designed for drying and transportation of plastic granulate. | |

| Capacity of basic machine: | 100 l |

| Maximal working temperature: | 160 °C |

| Conveyor height: | 3 m |

| Conveying pressure: | 0.055 bar |

| Acquisition year: | 2006 |

| The contact person: | Michal Staněk, stanek@utb.cz |

Blowing Machine

GDK | GM 251 EP

| Blowing Machine – designed for the production of hollow objects to a nominal volume of 0.35 l. | |

| Clamping force: | 11.5 kN |

| Processing performance: | 7 kg.h-1 |

| Maximal stroke: | 150 mm |

| Acquisition year: | 2009 |

| The contact person: | Michal Staněk, stanek@utb.cz |

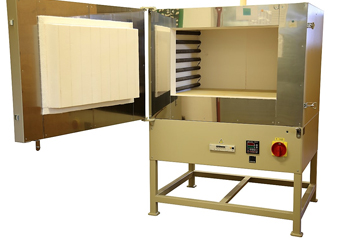

Curing Furnace (superkanthal)

Clasic CZ | 1018S

| Curing Furnace – designed for heat treatment of materials (sintering). | |

| Maximal temperature: | 1 800 °C |

| Internal dimensions: | (200 x 170 x 300) mm |

| Materials: | ceramics, glass, metals |

| Acquisition year: | 2012 |

| The contact person: | Berenika Hausnerová, hausnerova@utb.cz |