Measuring, testing machines, measuring instruments, optical in-struments, sensors, charge amplifier and data acquisition

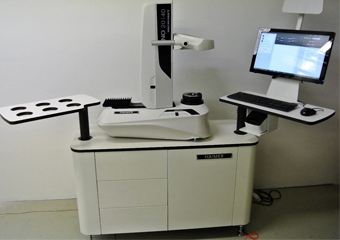

Presetter Tool

Haimer | Microvision UNO 20/40

| Presetter Toll – designed for fast and accurate measurement and tool setting. | |

| Maximal tool diameter: | 400 mm |

| Repeatability: | ± 2 µm |

| Maximal tool weight: | 60 kg |

| Acquisition year: | 2019 |

| The contact person: | Ondřej Bílek, bilek@utb.cz |

Melt Flow Indexer

Dynisco | Keyeness LMI 4003

| Melt Flow Indexer – device for measuring Melt Flow Index (MFI) as a basic flow data for plastics manufactures. | |

| The volume of the test body: | (8 – 12) cm3 |

| Operating Temperature: | 425 °C (± 0.1 °C) |

| Nominal load: | (1.2; 2.16; 3.8) kg |

| Compliant Standards: | ASTM D1238 & D3364, ISO 1133, BS2782 |

| Acquisition year: | 1997 |

| The contact person: | Michal Staněk, stanek@utb.cz |

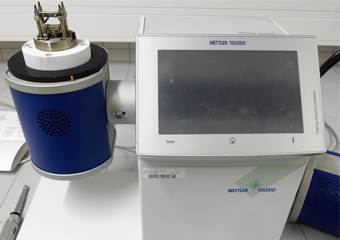

Dynamic Mechanical Analyzer (DMA)

Mettler Toledo | DMA 1 Star System

| Dynamic Mechanical Analyzer – mechanical and viscoelastic properties. | |

| Force range: | (0.001 – 10) N |

| Frequency range: | (0.001 – 300) Hz |

| Displacement range: | ± 1 mm |

| Teperature range: | (-190 – 600) °C |

| Acquisition year: | 2015 |

| The contact person: | Dagmar Měřínská, merinska@utb.cz |

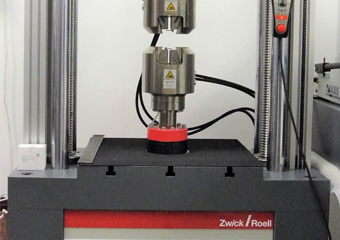

High-Frequency Pulsator

Zwick/Roell | Vibrophore 100

| High-Frequency Pulsator combines electro-magnetically excited dynamic testing machine with a fully functional static testing possible by ‘two in one’ function developed by Zwick/Roell. It can also be used as a full-scale static testing machine up to 100 kN. | |

| Maximal force: | 100 kN |

| Force amplitude max: | 50 kN |

| Maximal oscillation displacement: | 3 mm |

| Test frequency range: | (30 – 285) Hz |

| Maximal test height: | 1200 mm |

| Test SW: | testXpert |

| Acquisition year: | 2018 |

| The contact person: | Milan Žaludek, zaludek@utb.cz |

Servo-Hydraulic Dynamic Testing Machine

Zwick/Roell | HC 25

| Servo-Hydraulic Dynamic Testing Machine – standard fatigue and flexural tests. | |

| Test load in tensile: | 25 kN |

| Top crosshead adjustment stroke: | 700 mm |

| Test SW: | testXpert |

| Acquisition year: | 2018 |

| The contact person: | Milan Žaludek, zaludek@utb.cz |

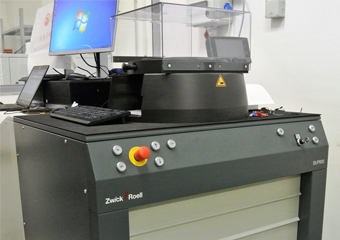

Sheet Metal Testing Machine

Zwick/Roell | BUP 600

| Sheet Metal Testing Machine used to determine and evaluate sheet metal properties. Typical test methods include Erichsen cupping tests (DIN 50100:2016, EN ISO 20482), in which a hemispherical punch is pressed into a clamped test piece until a crack appears. | |

| Maximal test load: | 600 kN |

| Maximal sheet thickness: | 10 mm |

| Blank (punchable): | 250 mm |

| Acquisition year: | 2018 |

| The contact person: | Michal Staněk, stanek@utb.cz |

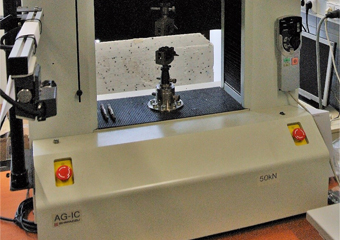

Static Materials Testing Machine

Zwick/Roell | 1456

| Static Material Testing Machine used to determine the properties of a material under static loads of tension, pressure and bending. | |

| Maximal test load: | 20 kN |

| Testing SW: | testXpert |

| Acquisition year: | 1994 |

| The contact person: | Milan Žaludek, zaludek@utb.cz |

Temperature Chamber

Zwick/Roell | W91255

| Temperature Chamber – designed for measurements in a wide range of temperatures. | |

| Temperature range: | -80 °C to 250 °C |

| Acquisition year: | 1994 |

| The contact person: | Milan Žaludek, zaludek@utb.cz |

Grinder-Polisher

Buehler | AutoMet 250

| Grinder-Polisher – designed for manual or automated sample preparation. | |

| Platen Wheel Speed: | (10 – 500) rpm |

| The number of samples in the holder: | max. 6 |

| Polished sample diameter: | 40 mm |

| Platen diameter: | 203 mm, 254 mm |

| Acquisition year: | 2011 |

| The contact person: | Martin Ovsík, ovsik@utb.cz |

Compression Mounting

Buehler | SimpliMet 1000

| The automatic Compression Mounting press is designed for rapidly transforming cut samples to specimens ready for grinding and polishing. | |

| Dimensions of the press: | (406 x 546 x 57) mm |

| Operating pressure: | (80 – 300) bar |

| Operating temperature: | (150 – 180) °C |

| Acquisition year: | 2011 |

| The contact person: | Martin Ovsík, ovsik@utb.cz |

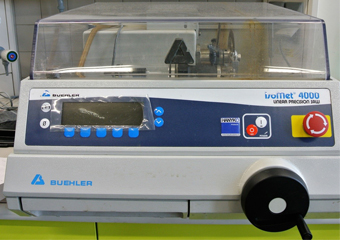

Linear Precision Saw

Buehler | IsoMet 4000

| Linear Precision Saw cut materials with minimal specimen deformation and low kerf loss. A wide selection of vises allow the user to precisely section virtually any material including metals, ceramics, composites, cements, laminates, plastics, electronic components, and biomaterials. | |

| Dimensions of the saw: | (406 x 546 x 57) mm |

| Feed rate: | (1.2 – 19) mm.min-1 |

| Maximal blade speed: | 5 000 rpm |

| Acquisition year: | 2011 |

| The contact person: | Martin Ovsík, ovsik@utb.cz |

Integral Universal Hardness Tester

Easydur (AFFRI) | Integrale 2E

| Integral Universal Hardness Tester – designed for different hardness tests: Brinell, Vickers, and Rockwell. | |

| Metods: | HRA, HRC, HRD, HRB, HR 15N-45N, HR 15T-45T, HV 10-60, HB 2.5-10 |

| Load: | (1 – 300) kg |

| Acquisition year: | 2007 |

| The contact person: | Martin Ovsík, ovsik@utb.cz |

Portable Leeb Hardness Tester

G+R Technology | HT-2000A

| Portable Leeb Hardness Tester is small size and portability of the Leeb tester allow them to test large and heavy forgings or castings. | |

| Metods: | HL, HV, HB, HRB, HRC, HSD |

| Test range: | (200 – 900) HL |

| Acquisition year: | 2009 |

| The contact person: | Martin Ovsík, ovsik@utb.cz |

Microhardness Tester

AFFRI | Microhardness DM2D

| Microhardness Tester – designed for micro and macro Vickers and Knoop method, single or multiple indentations. | |

| Test loads: | (0.0098 – 9.807) N |

| Acquisition year: | 2007 |

| The contact person: | Martin Ovsík, ovsik@utb.cz |

Universal Test System

Prominent | PROMI-PC

| Universal Test System – computer-controlled test system for tensile, compression, bending, spring testing and other types of tests. The system consists of a test bench with a digital power supply of the engine and a control unit of a personal computer. | |

| Tests load: | (0 – 3000) N |

| Main working stroke: | 450 mm |

| Acquisition year: | 2005 |

| The contact person: | Vladimír Pata, pata@utb.cz |

Impact Pendulum

CEAST | 696300

| Impact Pendulum – designed for determining the resilience of thermoplastic materials to impact. Designed to perform Charpy, Izod, tensile impact | |

| Hammer energies ranging: | 7.5 J |

| Velocities: | 3.7 m.s-1 |

| Acquisition year: | 2008 |

| The contact person: | Milan Žaludek, zaludek@utb.cz |

Bench Top Hardness Tester

AFFRI | IRHD

| Bench Top Hardness Tester – designed for automatic hardness measurements on plastic, rubber and systhetic fibers. | |

| Tests load: | (0.0098 – 9.807) N |

| Methods: | IRHD, Micro IRHD, Shore A, D, O, OO |

| Acquisition year: | 2007 |

| The contact person: | Martin Ovsík, ovsik@utb.cz |

3D Optical Surface Profiler

Zygo | NewView 8000

| 3D Optical Surface Profiler – designed for versatility in non-contact optical surface profiling. With the system, it is easy and fast to measure a wide range of surface types, including smooth, rough, flat, sloped, and stepped. All measurements are nondestructive, fast, and require no sample preparation. | |

| Repeatability: | to 0.12 nm |

| Maximum vertical scan speed: | 96 µm.s-1 |

| Scanned profile height range: | (150 – 20000) µm |

| Field of view: | (0.04 – 16) mm |

| SW: | Streamlined Mx™ |

| Acquisition year: | 2018 |

| The contact person: | Vladimír Pata, pata@utb.cz |

High-Resolution 3D Surface Profiling System

Taylor+Hobson |Talysurf CLI 500

| High-Resolution 3D Surface Profiling System – versatile, high range, high resolution system for automated surface finish and contour inspection. | |

| Workspace: | (50 x 50 x 50) mm |

| Weight capacity: | 10 kg |

| SW: | Talymap GOLD |

| Acquisition year: | 2009 |

| The contact person: | Vladimír Pata, pata@utb.cz |

Interferometric Laser Encoder

Renishaw | XL 80

| Interferometric Laser Encoders – laser interferometer system specifically designed for position feedback applications. | |

| Compensated system accuracy: | ±0.05 ppm |

| Range: | (0 – 60) m |

| SW: | Carto |

| Acquisition year: | 2009 |

| The contact person: | Vladimír Pata, pata@utb.cz |

Contact Perthometer

Taylor+Hobson | Form Talysurf 50

| Contact Perthometer – instrument for simultaneous measurement of shape and surface profile. | |

| Traverse (measuring) length: | (0.1 – 50) mm |

| Run up distance required: | 0.3 mm |

| Measurement speed: | 1.0 mm.s-1 |

| Acquisition year: | 2015 |

| The contact person: | Vladimír Pata, pata@utb.cz |

Thermocamera

FLUKE | TiS 45

| Thermocamera – portable infrared camera designed for widespread use, including searching for devices, preventive and preventive maintenance, diagnostics, research and development. | |

| Resolution: | 160 × 120 (19 200 pixels) |

| Temperature range: | –20 °C to 350 °C |

| Acquisition year: | 2017 |

| The contact person: | Martin Řezníček, mreznicek@utb.cz |

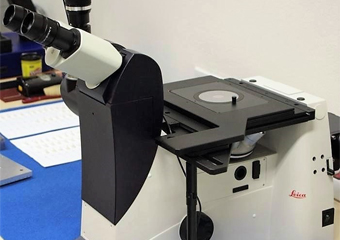

Inverted Manual Microscope

Leica | DMI 3000 M

| Inverted Manual Microscope – designed for materials science, industrial quality inspection and assurance, and new materials research and development, is easy to use with the possibility of connecting the camera. | |

| Maximum magnification: | 1000x |

| Acquisition year: | 2012 |

| The contact person: | Milan Žaludek, zaludek@utb.cz |

Digital Image Correlation System (DCI)

Sobriety | Mercury RT

| Digital Image Correlation System Deformation – designed for measurement of samples during material testing with use of the Video extensometer Mercury RT® allows applying multiple virtual probes (Movement Sensors), including the natural pattern of the sample surfaces. | |

| Cameras from: | Basler (2x – stereo) |

| Acquisition year: | 2018 |

| The contact person: | Jakub Javořík, javorik@utb.cz |

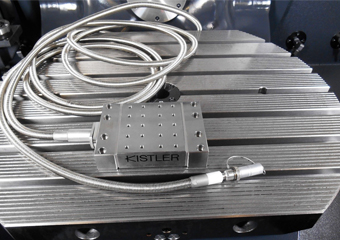

Compact Multi-Component Dynamometer

KISTLER | 9129AA

| Compact Multi-Component Dynamometer – designed for measuring the three components of the resultant force vector and the three components of the resultant moment vector | |

| Measuring range: | -10 kN to 10 kN |

| Sensitivity (rated): | Fx a Fz: 8.1 pc.N-1; Fy: 4.1 pc.N-1 |

| Linearity, all ranges: | ≤ ±0,3 ±%/FSO |

| Operating temperature range: | (0 – 70) °C |

| Acquisition year: | 2018 |

| The contact person: | Ondřej Bílek, bilek@utb.cz |

Charge Amplifier and Data Acquisition

KISTLER | 5167A81 and 5165A4

| Charge Amplifier and Data Acquisition – universal laboratory charge amplifier can be used wherever mechanical quantities are measured with multiple piezoelectric sensors. It covers slow, quasi-static signals as well as dynamic processes. | |

| Data for 5167A81: | |

| Number of channels: | 8 |

| Measuring ranges: | ± (100 – 1 000 000) pC |

| Operating temperature range: | (0 – 60) °C |

| Acquisition year: | 2018 |

| The contact person: | Ondřej Bílek, bilek@utb.cz |

Ceramic Shear Miniature Triaxial Accelerometer

KISTLER | 8763B050BB

| Ceramic Shear Miniature Triaxial Accelerometer – Integrated Electronics Piezoelectric (IEPE) triaxial accelerometer permitting vibration measurements in three mutually perpendicular axes: x, y and z. | |

| Acceleration range: | ± 50 g |

| Acceleration limit: | ± 100 g |

| Sensitivity at 100 Hz, 10 grms: | 100 ± 15 % mV.g-1 |

| Operating temperature range: | -54 °C to 100 °C |

| Acquisition year: | 2018 |

| The contact person: | Ondřej Bílek, bilek@utb.cz |

Impulse Force Hammer

KISTLER | 9722A2000

| Impulse Force Hammer – instrumented hammers are used to deliver a measurable force impulse (amplitude and frequency content) to excite a mechanical structure under test. A response signal measured with an accelerometer in conjunction with a FFT analyzer provides the transfer function of the structure. | |

| Measuring ranges: | (0 – 2000) N |

| Maximal force: | 10000 N |

| Sensitivity: | 2 mV.N-1 |

| Resonant frequency: | 27 kHz |

| Acquisition year: | 2018 |

| The contact person: | Ondřej Bílek, bilek@utb.cz |

Analytical Balance

KERN | ABT 320-4M

| Analytical Balance – single-cell weighing system. | |

| Maximal weighng capacity: | 320 g |

| Readability: | 0.1 mg.%-1 |

| Repeatability: | 0.1 mg.%-1 |

| Linearity: | 0.1 mg |

| Acquisition year:: | 2010 |

| The contact person: | Vladimír Pata, pata@utb.cz |